Smart Factory with IOT Orchestration Platform

The Powua IoT Orchestration platform enables real-time data acquisition from heterogeneous devices, integrates PLC (Programmable Logic Controller) and intelligent sensor data, and can be connected to external data sources such as SCADA, ERP, and CMMS. Additional non-intrusive sensors can be introduced to expand data collection. The data is extracted securely using the most common protocols in industry and transport the protocol used in your plant.

Powua is the only solution that directs preventive maintenance needs on condition and predictive; aggregates the information collected for control purposes and allows you to set alarms based on intervention and maintenance needs. In addition, it uses machine learning to perform condition analyzes and prognostic analyzes without requiring huge resources or a team of experts. Driven by Industry 4.0 / Industrial Internet of Things (IIoT), industrial operations are increasingly autonomous. The factories combine numerous sensors that provide real-time data on the status of production and machinery to optimize operations. Smart sensors are also increasingly used to control roads, cities, strategic infrastructure, transport, and smart vehicles. Powua is the only solution that offers scalable predictive monitoring and analytics, adapting to any IoT scenario.

Watch this video to learn everything about Powua for IoT in 60 seconds

Modules

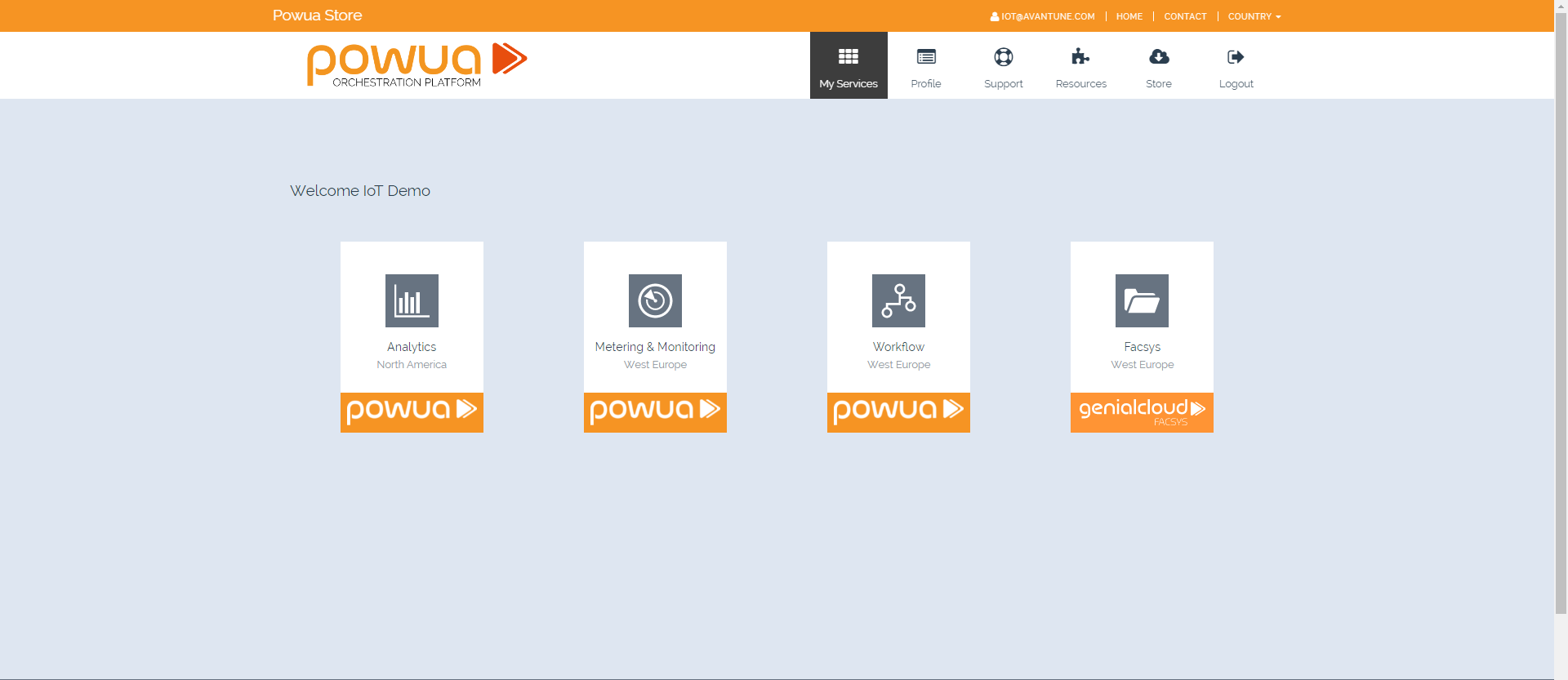

PORTAL

✓ End users can be enabled to view only the information they need, also accessible via cloud.

✓ Fully configurable to provide diversified services.

✓ Security features and user profiling.

✓ Single point of access and authentication (SSO, OAuth2).

✓ Complete management of activated services: variation and sharing with other users.

✓ Integrated with support and maintenance systems, which can be integrated with the solutions already present in the company.

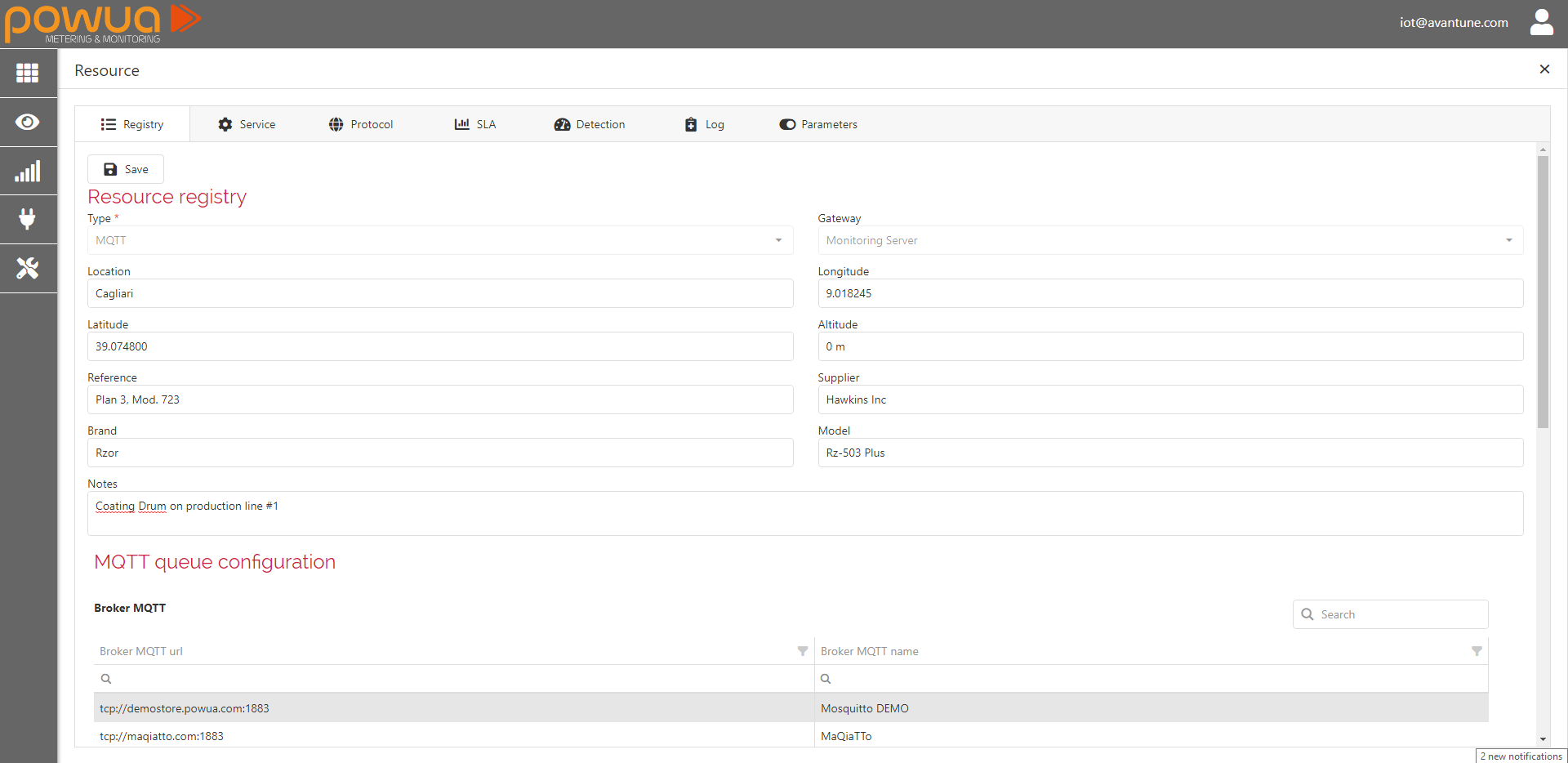

PROVISIONING

✓ Integrates a self-provisioning system for edge gateways that provide data detection from the IoT system.

✓ Allows the definition of the measures that have to be taken.

✓ It allows you to associate metadata to managed resources and to represent the entire IoT infrastructure on a map.

✓ Configurable and manageable by the user.

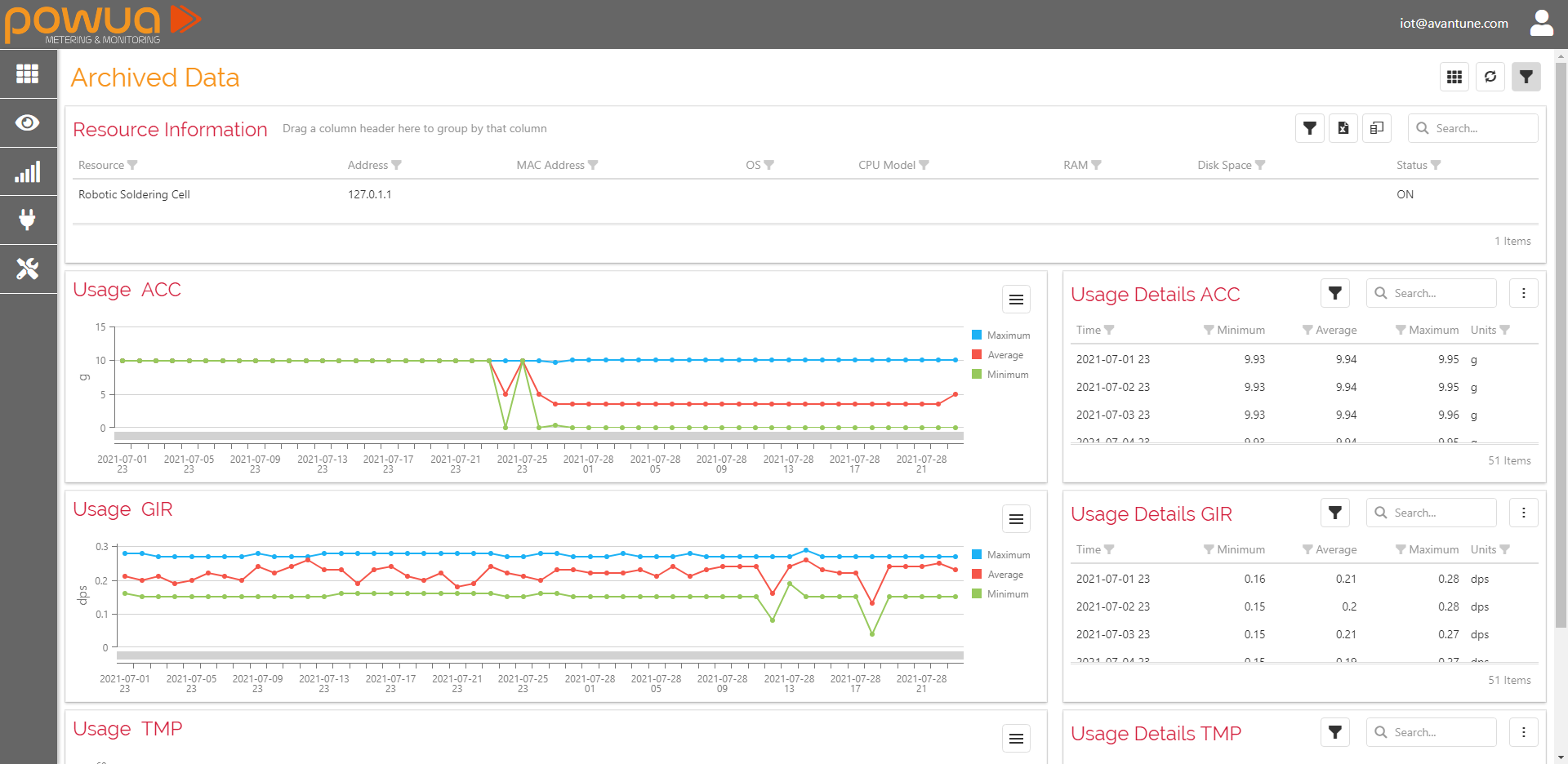

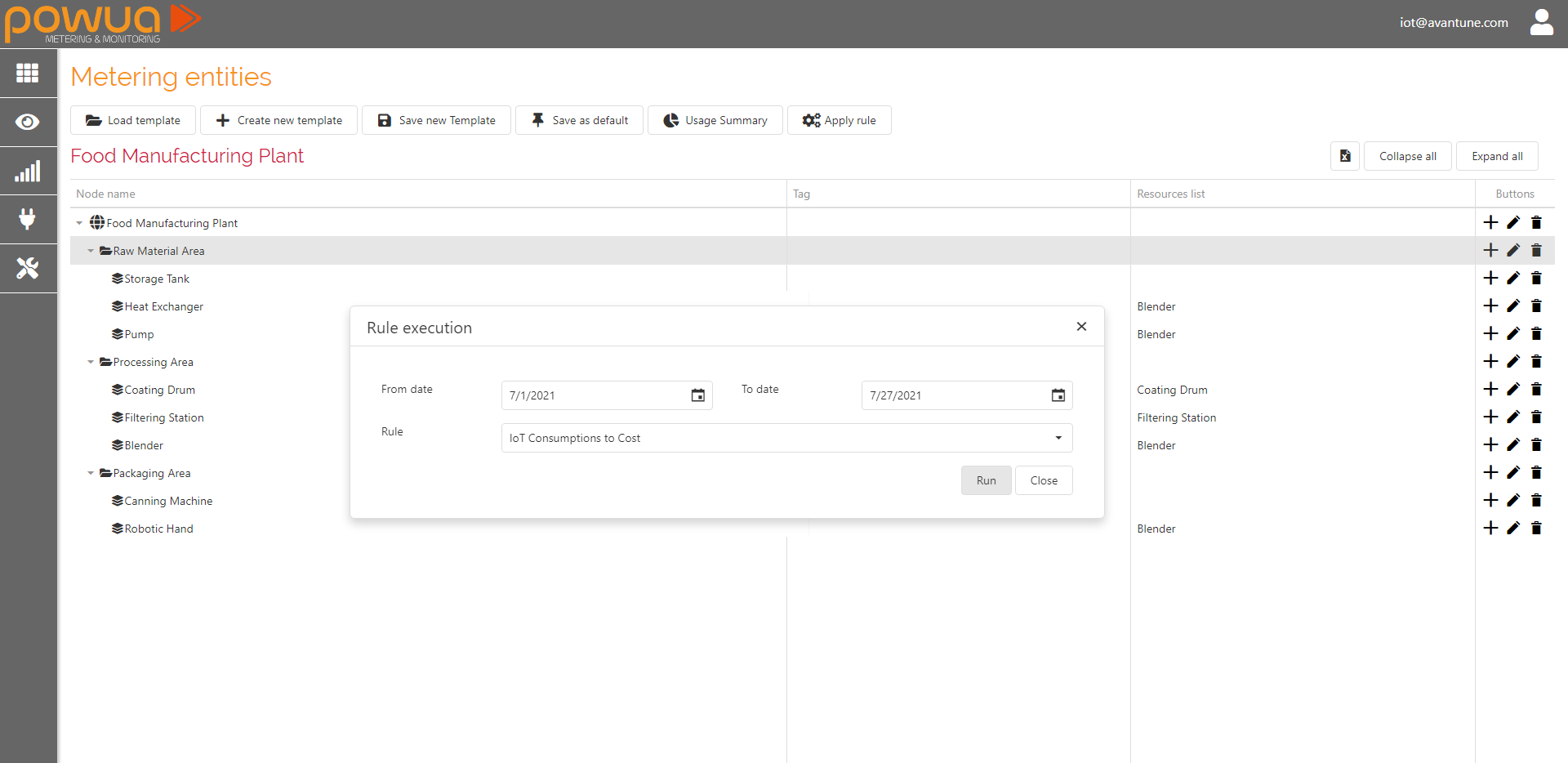

METERING

✓ Acquires the measurements collected in real-time and selectively.

✓ Transform acquisitions from heterogeneous systems for reading uniformity.

✓ Acquires measurement data through proprietary technology based on Software Edge Gateway, expandable via a plug-in.

✓ Powua Edge Gateway can be supplied already integrated with certified hardware gateways, in specialized control units for the transport sector, or can be integrated with third-party hardware.

✓ Native support for the following interfacing protocols: MQTT, HTTP, FTP, SSH, SNMP, JDBC, WMI, IP SOCKET, MODBUS, OPC UA.

✓ Helps to define hierarchical aggregation criteria for detected consumption (e.g. at plant, resource, production area level).

✓ Supports TAG attributions to measured assets, for analytical purposes.

✓ Can be integrated with a rules engine to implement complex processing or enhancement logics.

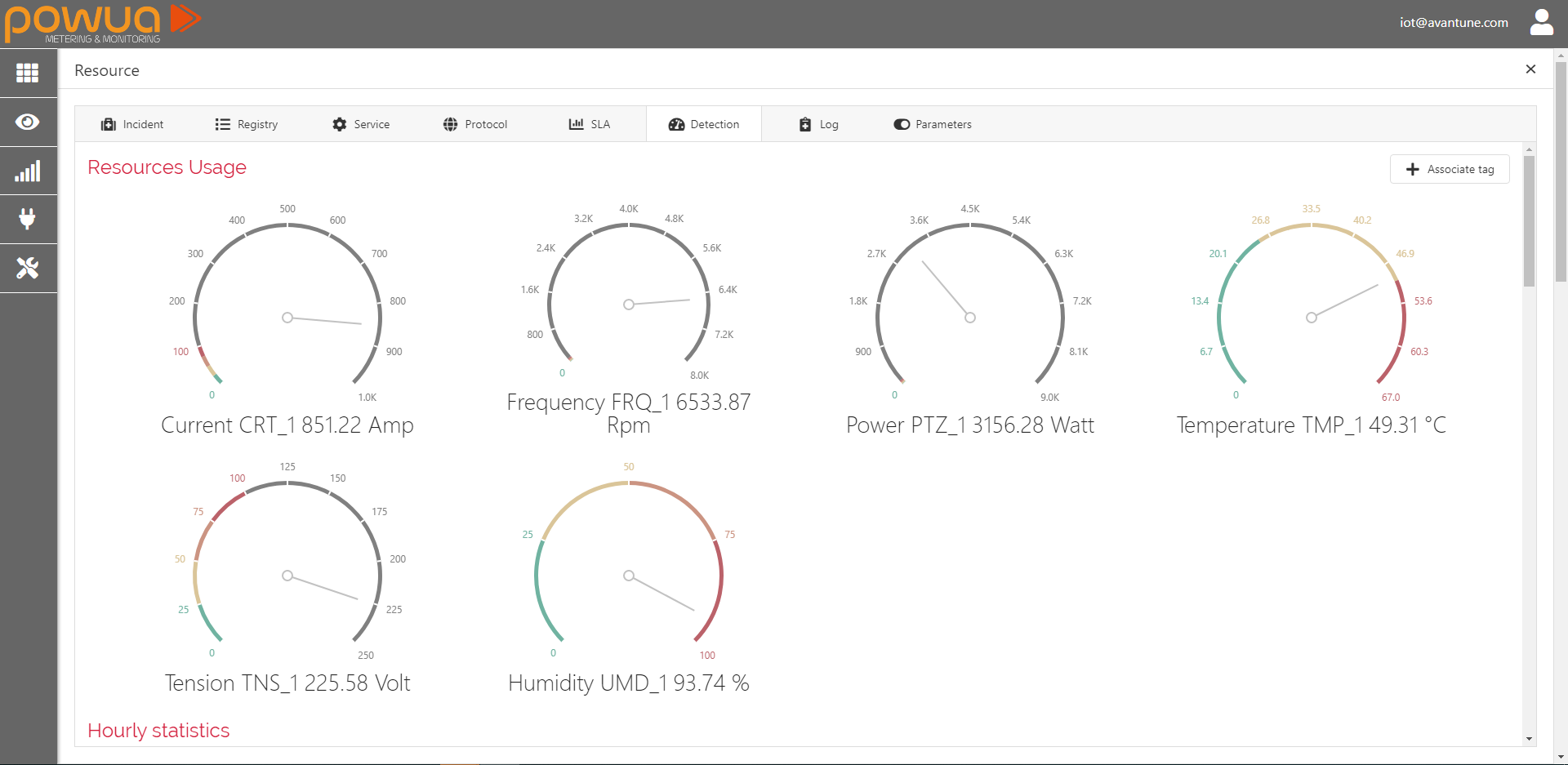

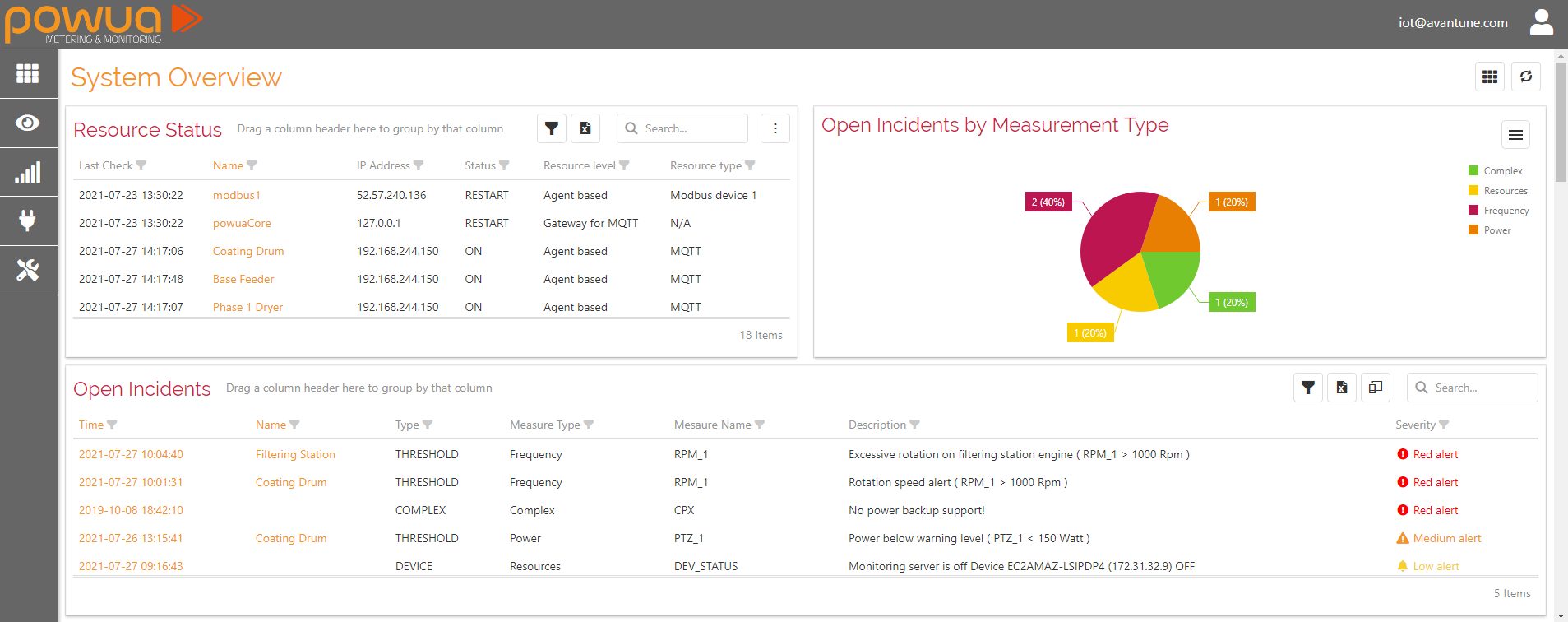

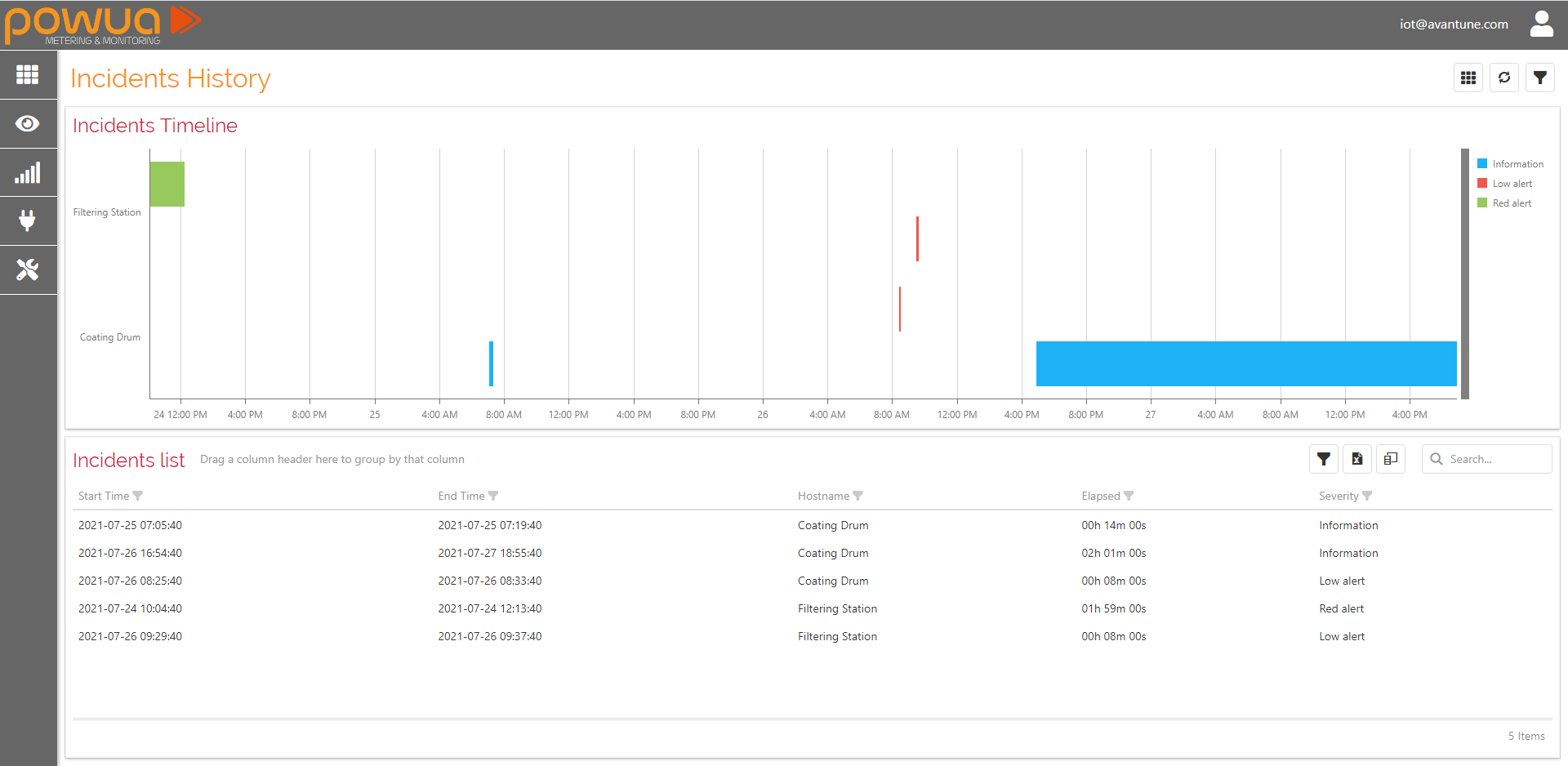

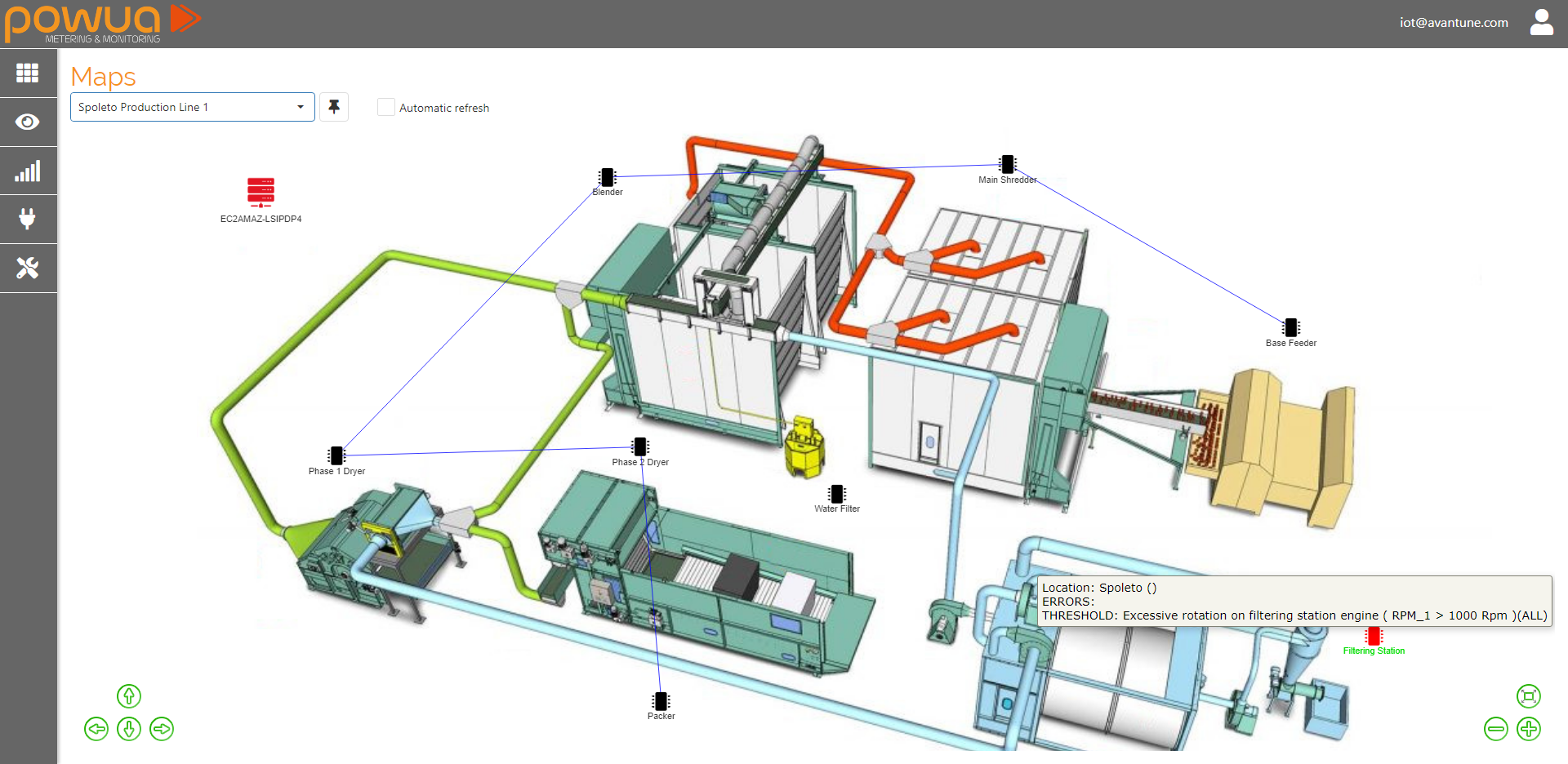

MONITORING

✓ Asset management both in terms of resources and components of the IoT system.

✓ Monitoring the operating status for resources and devices, based on the metrics detected.

✓ Definition of alarm thresholds following the occurrence of events.

✓ Creation of composite and complex alarms, starting from the monitored entities.

✓ Representation of resources and alarms on customized maps or geographic maps via geolocation.

✓ Hierarchical representation of the status of the monitored systems (e.g. at plant, resource, production area level).

✓ Automatic calculation of downtime and SLA by type of accident and resource.

✓ Can be integrated with other systems such as maintenance management systems.

RULE ENGINE

✓ Execution in interactive mode or on a scheduled basis to generate a constant information flow, to feed the Analytics, the A.I., or any external systems.

✓ Programmable through a simple scripting language.

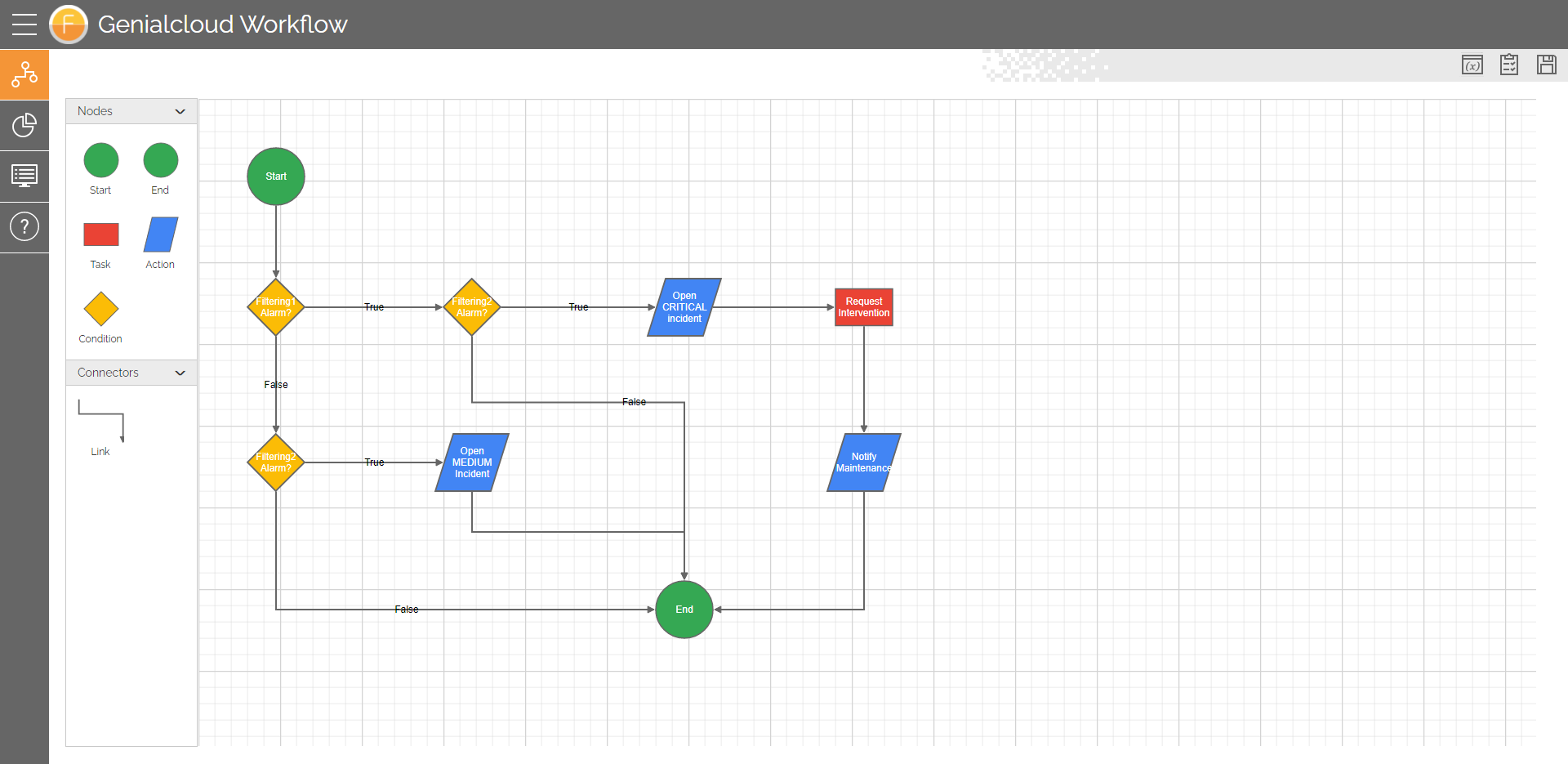

WORKFLOW

✓ Simple user interface to configure, create, manage and monitor business processes, such as maintenance, production, logistics, quality, etc.

✓ Real-time monitoring of any process and workflow status, through dashboards and reports; historical of the performed processes.

✓ Predefined and customizable activities and tasks, to meet the needs of implementing processes of any type.

✓ SDK to create new integrations.

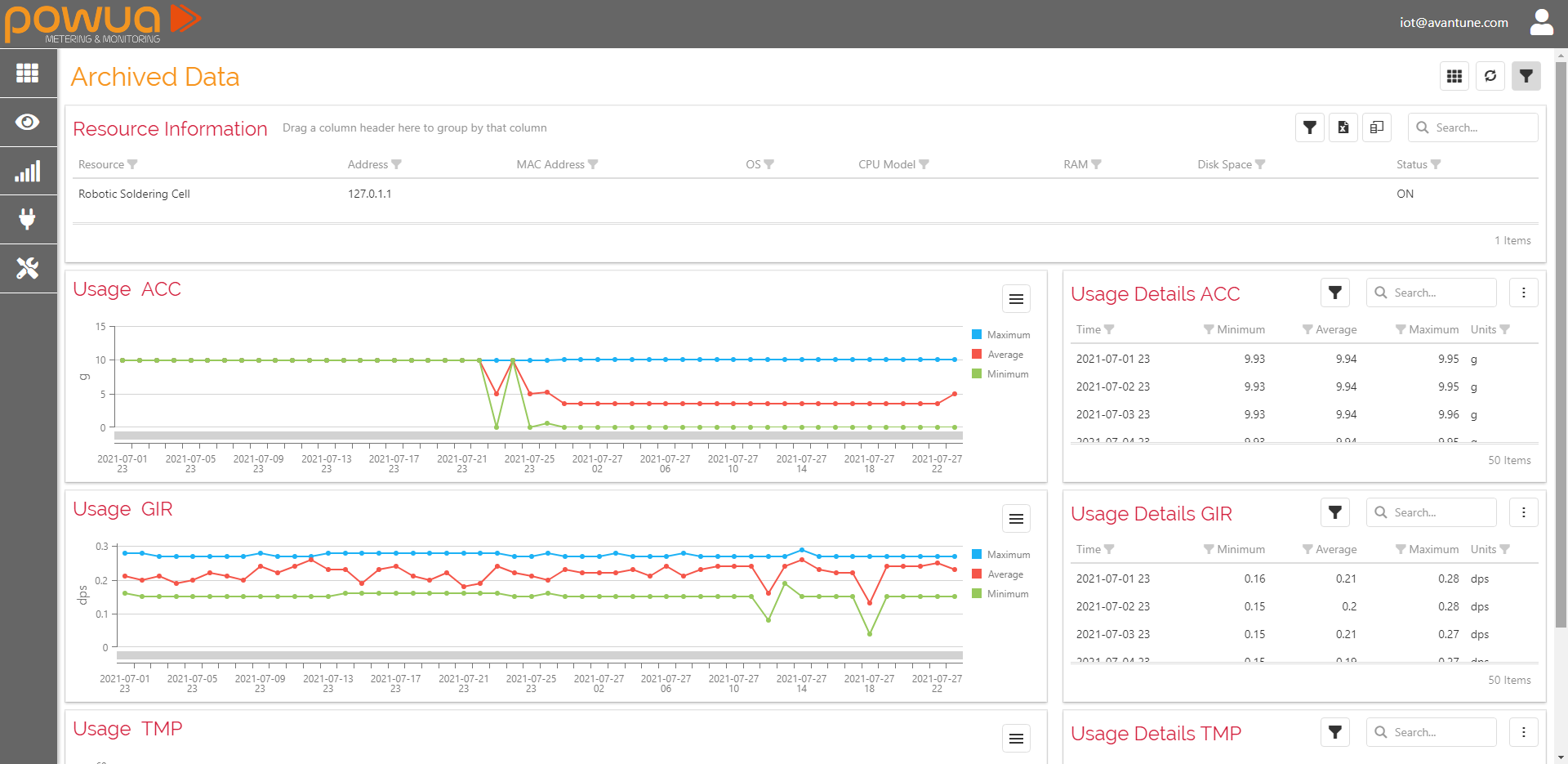

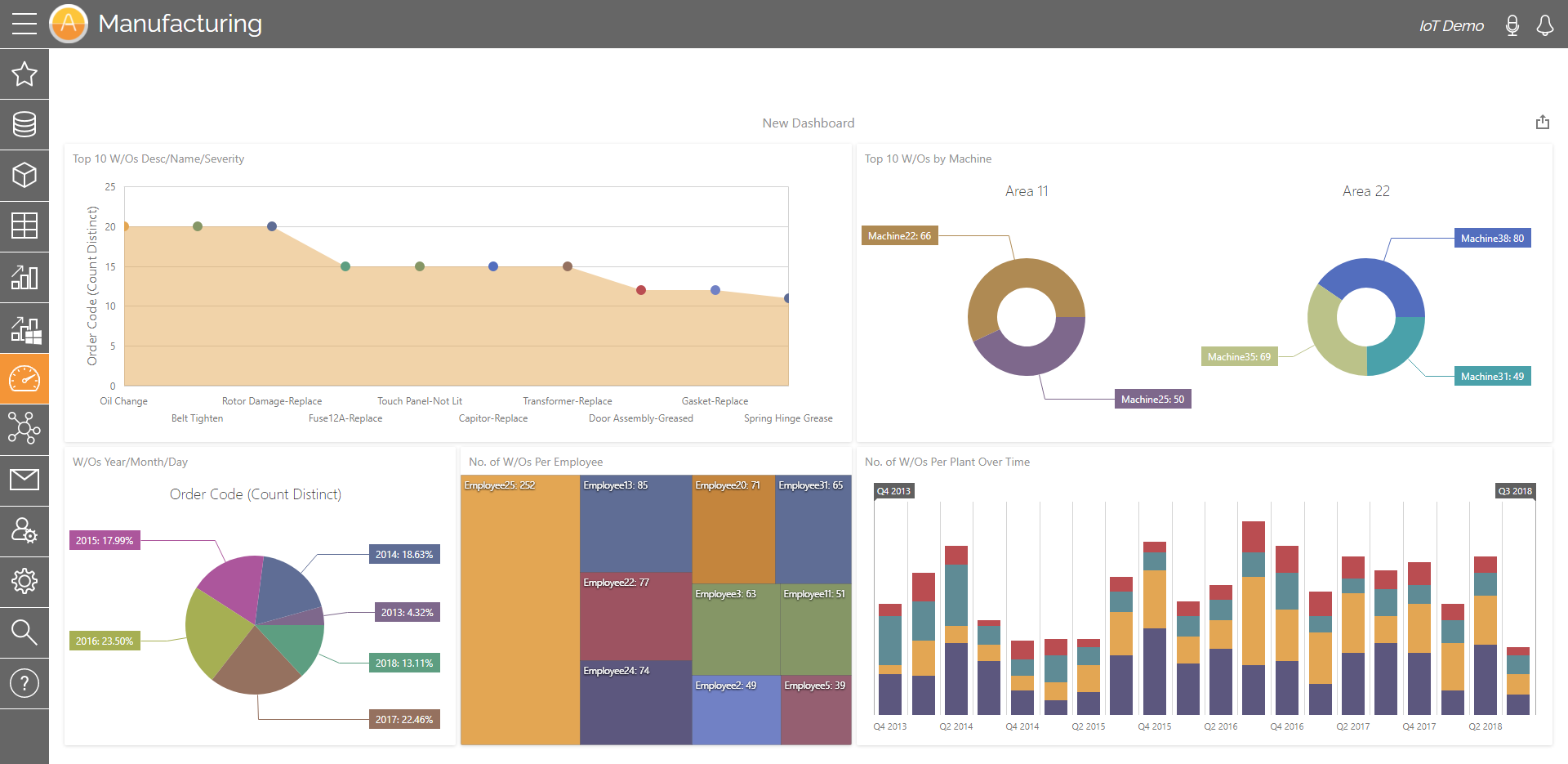

ANALYTICS

✓ Processing and aggregation of measurement and monitoring data, to analyze and optimize performance.

✓ Correlation with multiple external data sources (eg. ERP, MES, CMMS, etc ...) to analyze processes and introduce efficiency improvements.

✓ Guided creation of KPIs, views, dashboards, and reports to be shared interactively.

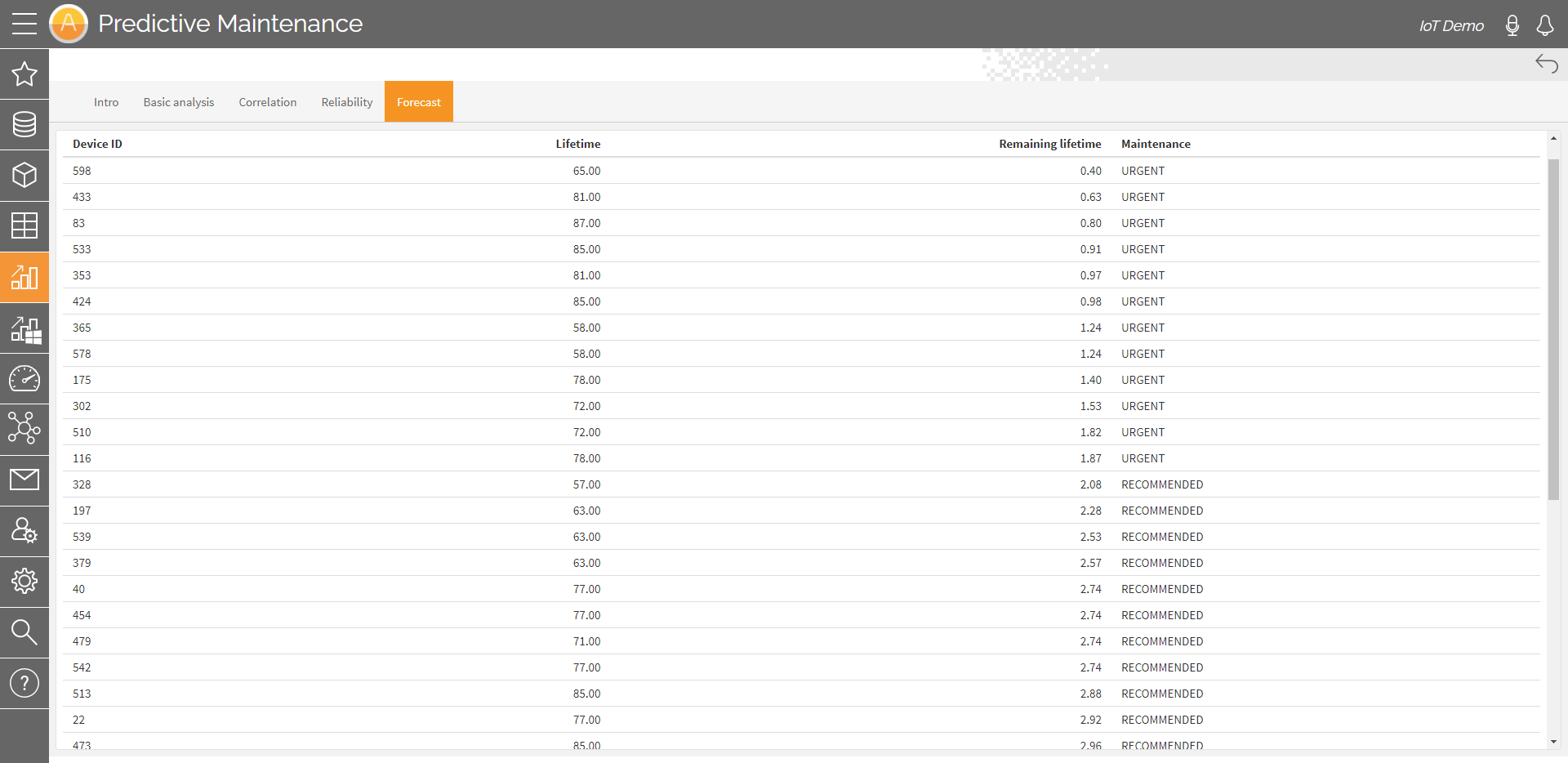

✓ Transformation of the acquired and aggregated data into useful information for preventive maintenance (on condition), optimization, and cost reduction.

ARTIFICIAL INTELLIGENCE

✓ Processing of machine data, historical data related to failures, repairs, operating conditions, maintenance requirements, and from additional data sources.

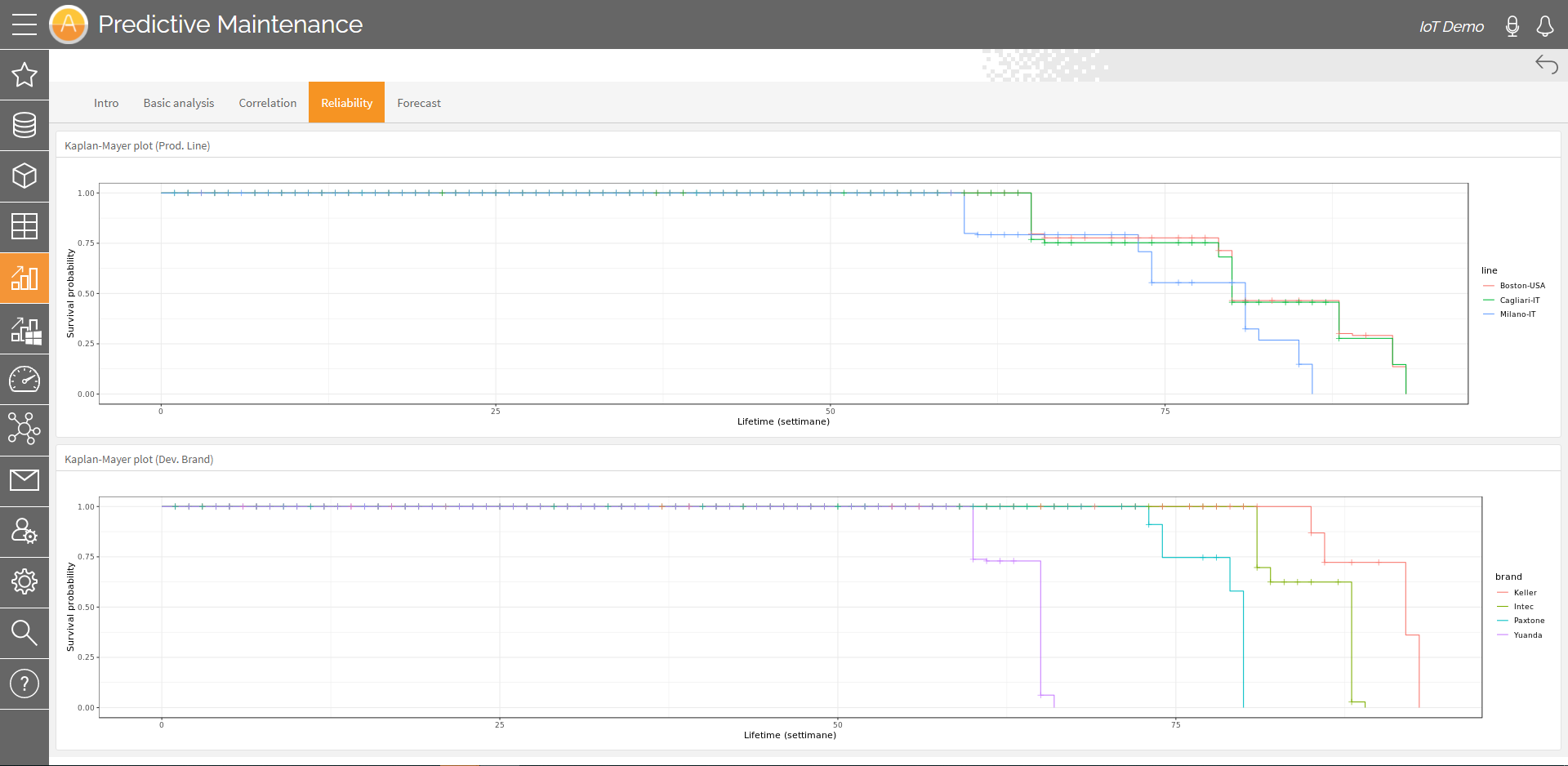

✓ Allows production or maintenance managers to predict the failure, identify performance anomalies and perform root cause analysis.

✓ Resolution of complex problems through the application of statistical algorithms, probability calculation, time series, machine learning, and deep learning.

✓ Based on the main reference tools and frameworks, it allows you to manage the entire life cycle, starting from the data flow generated by Powua and enriched with other data sources leads to the choice of the algorithm. Its implementation shows up representing the results in the form of interactive reports and dashboards, ease to use by the end-user.

Benefits

ABSTRACTION AND INDEPENDENCE FROM THE IoT SYSTEM

DATA VISUALIZATION WEB TOOLS

SCALABILITY AND ADAPTABILITY

DYNAMIC RULES AND WORKFLOW

ACCESSIBILITY AND AVAILABILITY

PROGRAMMING INTERFACES